alockbox

Well-known member

Ok so here is what I did. I used a pry tool to remove the coin holder. This is standard on the base Lariat.

I pried first the bottom and then the top with a second tool.

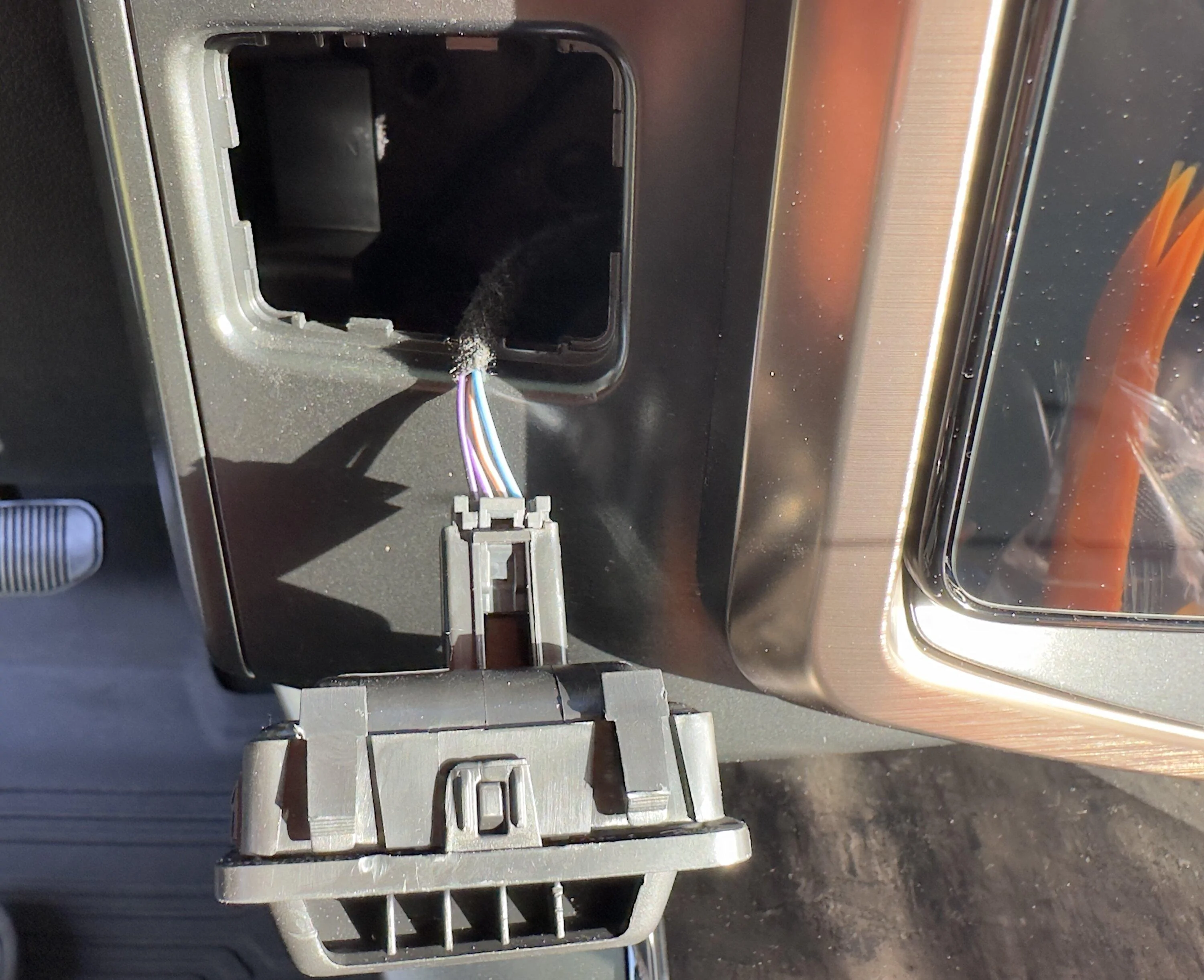

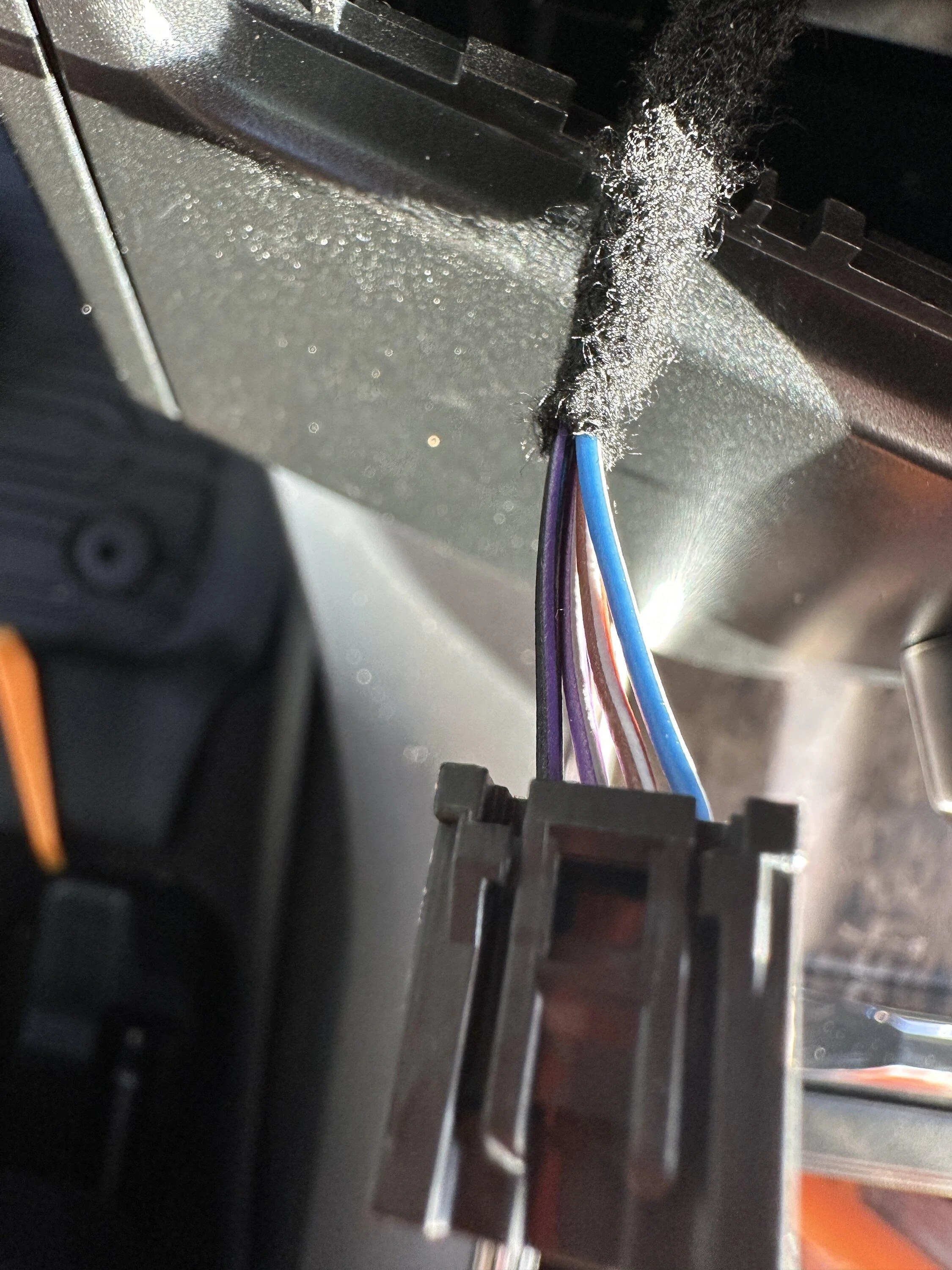

Interestingly, it has a harness attached to the back end. The harness has wires but the clip does not, it just dead-ends the signal. They must be using one complete harness for simplicity of production.

The coin holder is actually two pieces clipped together.

I had an AMPS 17mm ball mount I wanted to use. I had previously paired this with a MagSafe 17mm ball joint front-end, so I wanted to recreate that setup here.

I took measurements and cut some matte black acrylic into two adapter plates. One is the size of the coin holder trim and the other a little larger to sit behind the opening and sandwich the dash between them. The 4 holes are standard AMPS Mount spaces. While the mount plate itself could have worked as the front-end of the sandwich, it didn’t fill the space enough for me.

I pried first the bottom and then the top with a second tool.

Interestingly, it has a harness attached to the back end. The harness has wires but the clip does not, it just dead-ends the signal. They must be using one complete harness for simplicity of production.

The coin holder is actually two pieces clipped together.

I had an AMPS 17mm ball mount I wanted to use. I had previously paired this with a MagSafe 17mm ball joint front-end, so I wanted to recreate that setup here.

I took measurements and cut some matte black acrylic into two adapter plates. One is the size of the coin holder trim and the other a little larger to sit behind the opening and sandwich the dash between them. The 4 holes are standard AMPS Mount spaces. While the mount plate itself could have worked as the front-end of the sandwich, it didn’t fill the space enough for me.

Here’s how it looks assembled, only the plate on the left would be behind the dash. I tightened the assembly and put a dab of super glue gel on the perimeter of each nut to lock them in place on the rear plate. Once dry, I disassembled and then got to work installing it. I ended up drilling a 1/2” hole in the center of the rear plate to allow my finger to hold the plate as I pushed it into the dash then pressed it forward. I also applied some double sided foam tape to help hold it in place and minimize squeaks. It still took some time as I used shorter bolts, but it was doable.

The hardest part is aligning the rear plate before sticking it, so the front plate holes line up.

An easier way would have been to have the bolts come from the rear, glued in place, cut the right length, and used a capped nut. I just didn’t have any.

Finished product.

Sponsored

Last edited: