XLT Jeffy

Well-known member

- Joined

- Apr 15, 2022

- Threads

- 2

- Messages

- 98

- Reaction score

- 147

- Location

- Vancouver, BC

- Vehicles

- 2022 Ford Lightning XLT SR

Front visibility looks like it could be terrible with that A-pillar.

Sponsored

The Semi won.

agree, I think it doubles as a sleeping surface for camping mode. What a waste of spaceThat front dash is large enough to have a picnic on. It's so big it even has its own little windows! This video is probably the least ugliest I have seen yet but it is still yuck.

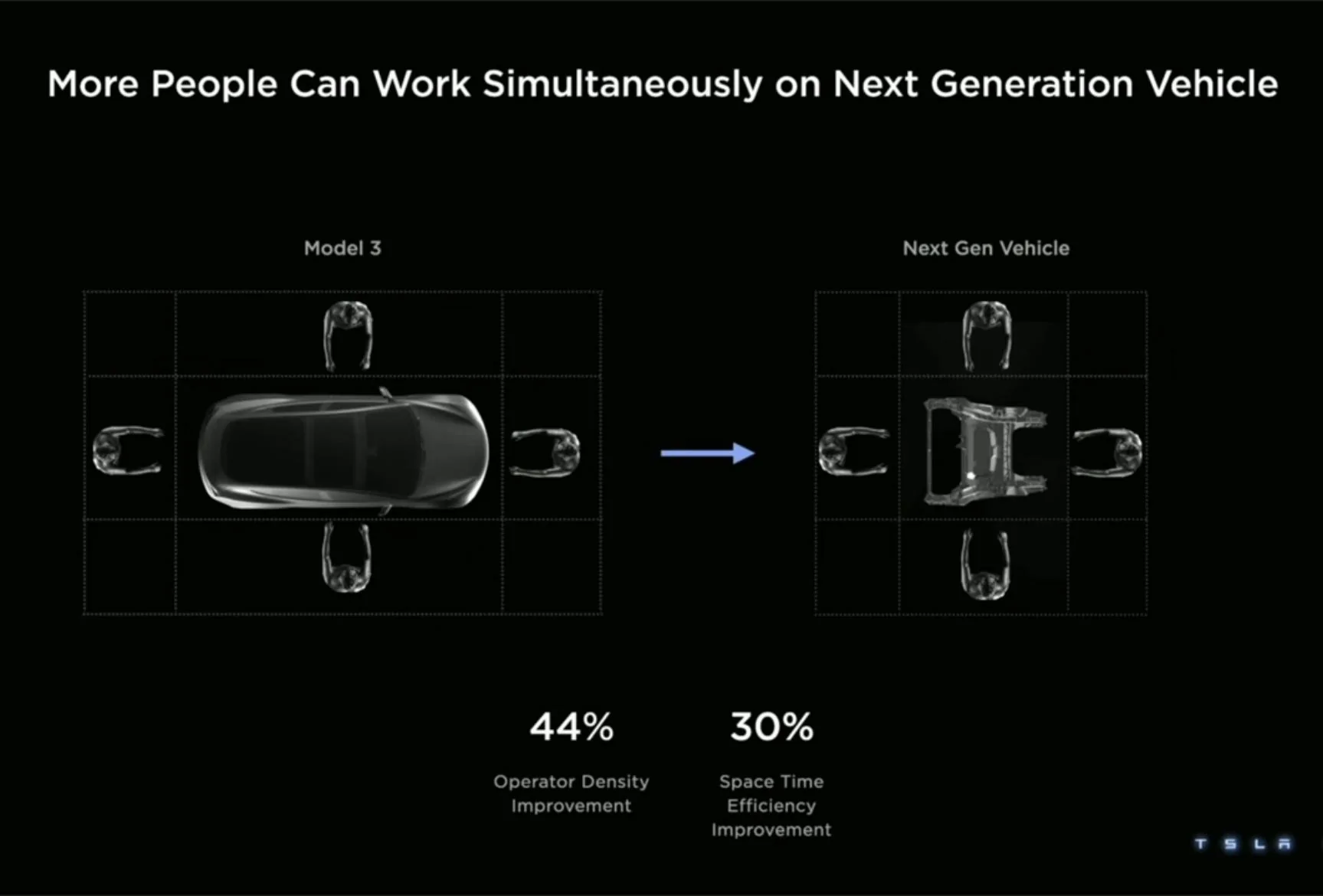

In terms of the giga press or making and using their own 48v architecture?Did anyone watch the tesla investor day presentation? Specifically the part how they’re going to be manufacturing the trucks and next gen cars? I know the presentation is meant to drive investment and pump the stock but I think tesla is on the brink of an iPhone moment to everyone else’s Nokia’s.

I mean the huge gains in efficiency in the factory build process. Large casts to reduce part numbers. 48v architecture. Simple interiors. Very few model trims/options for assembly line efficiency. Structural battery packs. This new generation car is going to be a big deal. Cybertruck will use the same methods AND not require paint. No dealers. All of this combined gives them a huge price advantage.In terms of the giga press or making and using their own 48v architecture?

I think Tesla is already running about as lean as you can get. That's not a bad thing, it is very effective, but I'm not sure how much more costs they can trim. I guess we'll see.

I don't think it will have nearly the impact you're suggesting. Most vehicles are already made in large casts and welded together. 48V does offer a lot, but they're not the first to discuss it, it just hasn't seen mainstream pick up yet. The simple interiors and similarity between vehicles and trims helps up to a point, eventually as more competitors hit the market people are going to ask why they are buying a Tesla if its spartan interior lacks against other vehicles. Structural battery packs, sure I guess, I'd need to see a mock up because I'd rather continue with something like Fords that has ease of access to replace. As for the image, I mean, that's pretty much already how it's done. Have you seen the videos of our Lightning being made? They build the bed and the cab and combine the two on the frame. I guess they could finish the cab's interior first but the idea that building portions of vehicles separately then bringing them together seems marginal at best and very far from an earth shattering modernization of manufacturing...I mean the huge gains in efficiency in the factory build process. Large casts to reduce part numbers. 48v architecture. Simple interiors. Very few model trims/options for assembly line efficiency. Structural battery packs. This new generation car is going to be a big deal. Cybertruck will use the same methods AND not require paint. No dealers. All of this combined gives them a huge price advantage.

For comparison, an XLT long range Lightning costs $100k here in Canada. The average joe just can’t afford that.

I hope, hope you are right and it like the Ford.That will come tonight. The beta front end was redesigned and you can now see the grill is part of the hood. This just shows the success and popularity of Fords Frunk has pushed Tesla to rethink the front end of the truck and include one.

I truly love that frunk on my lightning.I hope, hope you are right and it like the Ford.

Between the Rivian approach, and the Ford way, the Lightning wins hands down.

and looking at the roof lines, the headroom in the backseat must be much lower than the front seats.2nd row is squeezed.