Joe.....Montana

Well-known member

My build date is 12/23....my nuts might be affected

Sponsored

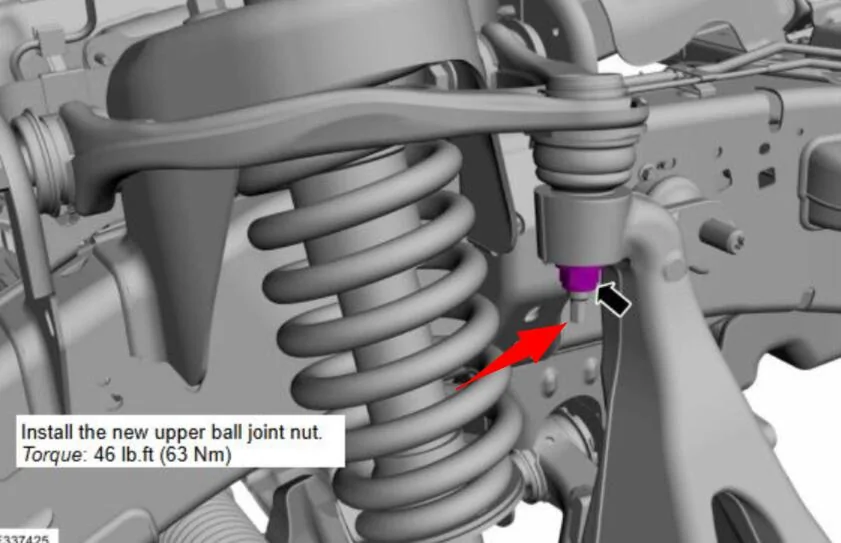

now does anyone have specs on what the torque should be on this nut?2024 Ranger had the exact same issue. Easy DIY if you have a torque wrench.

Post 12now does anyone have specs on what the torque should be on this nut?

Erm... I've got a quality torque wrench, but don't you have to hold the bolt (red arrow) so you can get the correct torque on the nut (black arrow)? Otherwise, isn't the thing is just going to spin?Mine is a 12/23 build, and yikes! Passenger side had maybe 10 ft-lbf on it, driver more like 30.

Definitely don’t recommend relying on visual inspection!

Ball Joints use a shallow angle taper that is self locking and should not require holding the indicated hex in this condition. A torque wrench that will allow you to hold that hex and torque isErm... I've got a quality torque wrench, but don't you have to hold the bolt (red arrow) so you can get the correct torque on the nut (black arrow)? Otherwise, isn't the thing is just going to spin?

To do this correctly do I put the torque wrench on the bolt and hold the nut with a box wrench?

I agree with this. A castelated nut and cotter pin would keep this from being an issue. Of course, you'd still want to tighten it down to spec, but, the cotter pin would keep it from completely coming apart in the short term.Looking at the photos one can see how this is assembled at the factory.

There is a hex on the ball joint shaft that is held by the installation tool as

the nut is run down.

During my days as a Ford Mechanic, shortly after the earth cooled, Ball Joints

and Tierod ends used Castelated Nuts and cotter pins. There was a torque spec

but it did not matter as there was no guarantee that the cotter pin could be installed

at that torque. If the holes did not match, you Always tighten the nut never loosened

to install the cotter pin. This system was easily visually checked. Something the

current system can not be. I guess this is progress, but the older system was far more

fail resistant than this new system. The new system does not require as many humans

so possibly cheaper. If this system makes many of these errors it might not be cheaper!

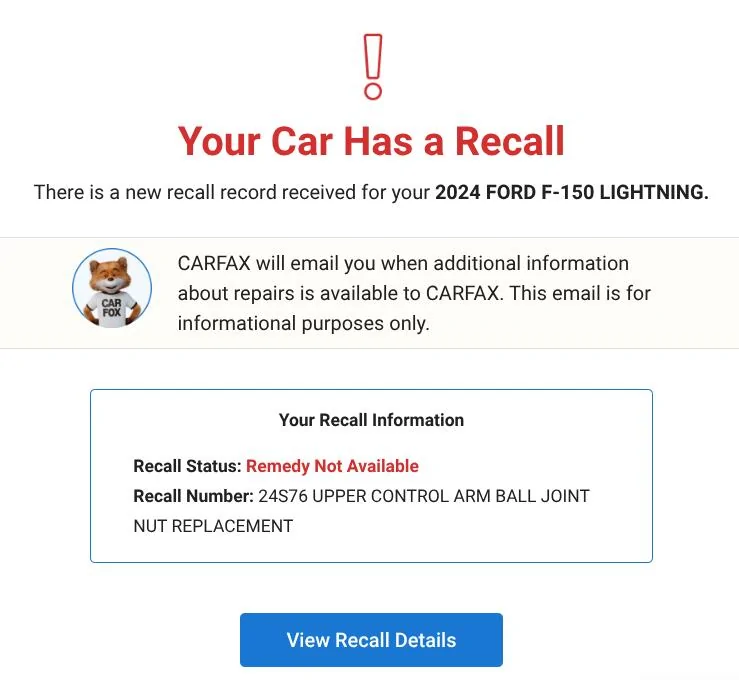

Ah, well that may explain why the recall notice I got from CarFax says that there isn't a remedy yet.My SA and I were talking about this the other day, and he said this problem was first brought up or found on Broncos. He told me that they had to replace the ball joint if the nut was loose because there was no way of knowing whether there had been any damage to the stud due to the loose nut. You can't simply just replace the nut and torque it down without knowing if damage was done to the shaft, so you have to replace the ones that were loose. So obviously I haven't seen the repair instructions and don't know what will be called out, but it's my assumption that what happened on the Bronco recall will happen with the Lightnings.

Might just be that Ford isn't actively resolving the issue now. They're not even sending out the notices until February.Well, got my first formal notice...from CarFax! Well, that's good, but it says "Remedy Not Available". I wouldn't think that nuts would be a big back-order item.